With social media at all of our fingertips, it's hard to stay up to date on our blog. However, since we'd like to keep this page as relevant as possible, we thought it would be cool to share with you some of the stages of our production. Here is a rough rundown on some of the time-intense love & labor involved going into each wallet we produce. Enjoy!

1. Before we do anything, we apply a treatment to the backside of each hide of leather. This special teatment seals and stiffens the leather. After that, we punch out each rectangle of leather & thumb slot, one at a time, from a hide of imported Italian leather. Once that is complete, we move on to the embossing, where each logo is pressed into the leather by hand. The result is this:

2. Next we apply the utility nylon liner. Using a special adhesive, one side of the liner is glued to the inside of the wallet. After it has cured, each wallet is flipped and the the other side of the liner is adhered in place.

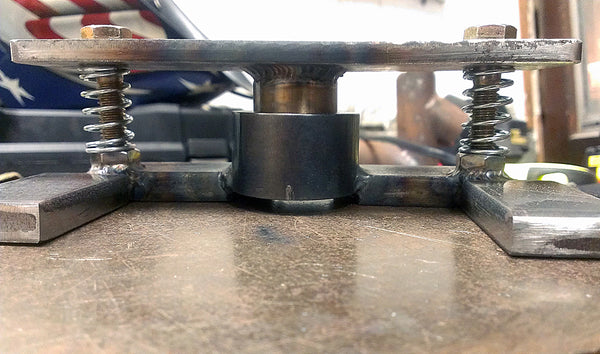

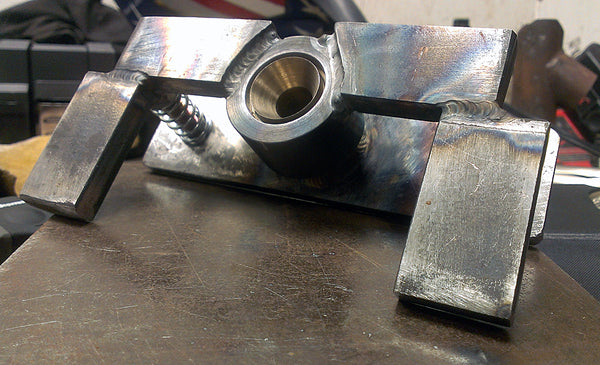

3. After the liner adhesive is full cured, we take the wallets over to punch the center-panel notch. This is done on a spring-loaded jig we fabricated ourselves. Once each of the notches is punched out of the wallet, we apply a special edge coat to the unfinished and freshly cut edges.

4. Next we move on to temporarily gluing in the custom made elastic. Our elastic comes on giant rolls, so first each piece needs to be cut to size off the roll. This process is done with a hot knife. After we cut each piece, it is then glued to the back side of each wallet, wrapping the edges around to the center. Another jig we fabricated is used to align each piece, and remember, each wallet is done one at a time. Once that glue cures, we fold and glue the wallet closed - to what will be it's final shape.

5. After that, it's on to stitching!

6. Once the wallets are stitched, we go through our quality control process where test each one and go over all the details. If the wallet meets our high standards, we apply the final the step - Hand-waxing! The leather conditioner we use contains a natural beeswax, so waxing each wallet not only beautifies, strengthens, and conditions the leather, it also helps waterproof it and ensures your wallet a durable long life.

I hope this brief rundown of the basic steps involved in making each one of our wallets helps you appreciate the time and care put into each one, as well as give you an understanding of how the production process on our end works. We're proud to say that each wallet we make is 100% handcrafted in the good ol' USA.